Maximize research and production results with Pilot Scale Bioreactor

Key strategies for effective scalability in pilot scale bioreactors

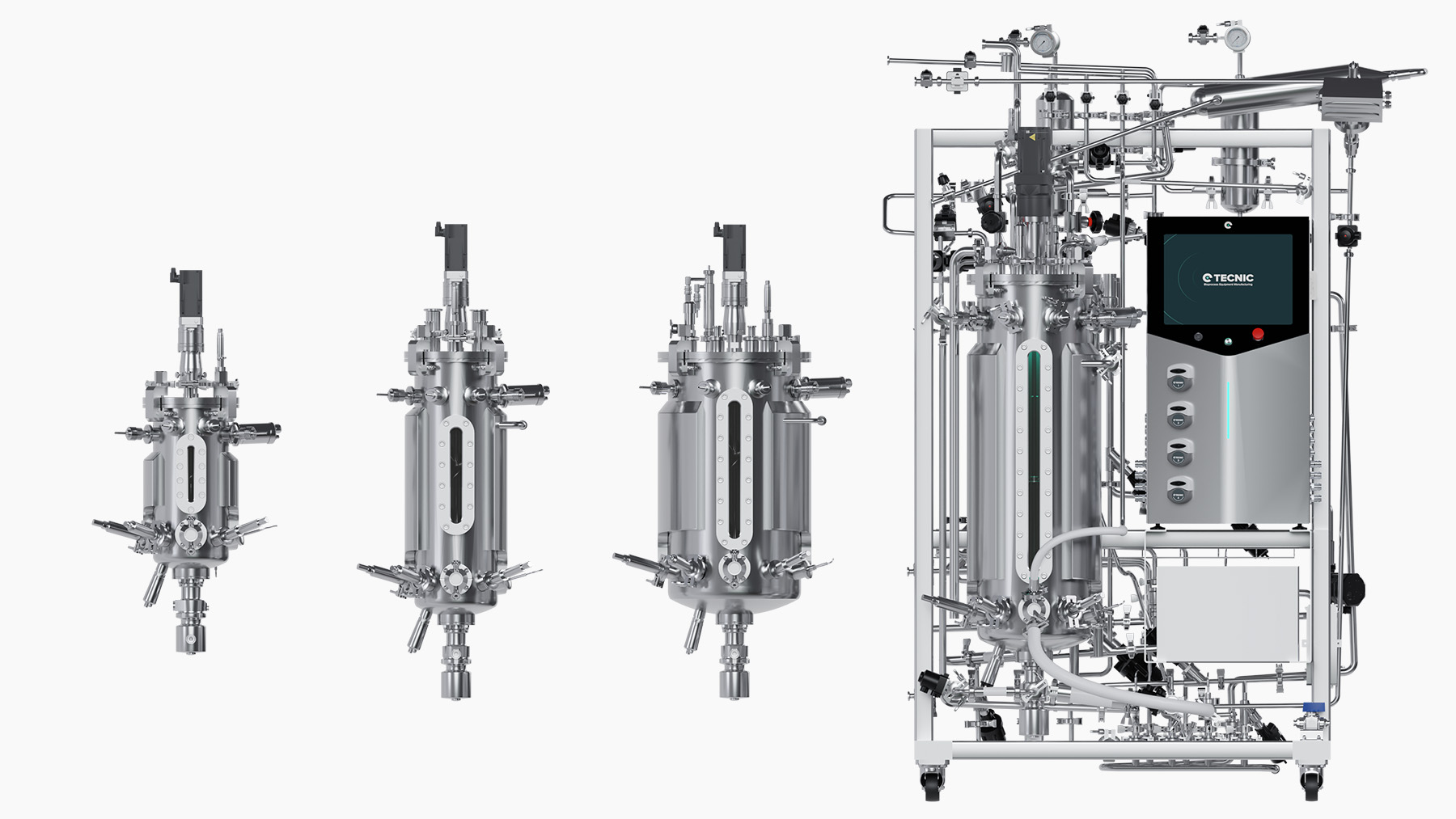

TECNIC ePILOT Bioreactor offers a unique solution in scalability and adaptability, allowing for the interchangeability of vessels1 between the cellular and microbial versions. Essential for laboratories and production plants, seeking flexibility in their cell culture and microbial fermentation processes.

With working volumes of 10, 20, 30, and 50 liters, the interchangeable vessels of the ePILOT facilitate the transition between different scales of production or research, without the need to invest in multiple systems. The bioreactor is dedicated to precision and adaptability, with real-time monitoring through integrated sensors.

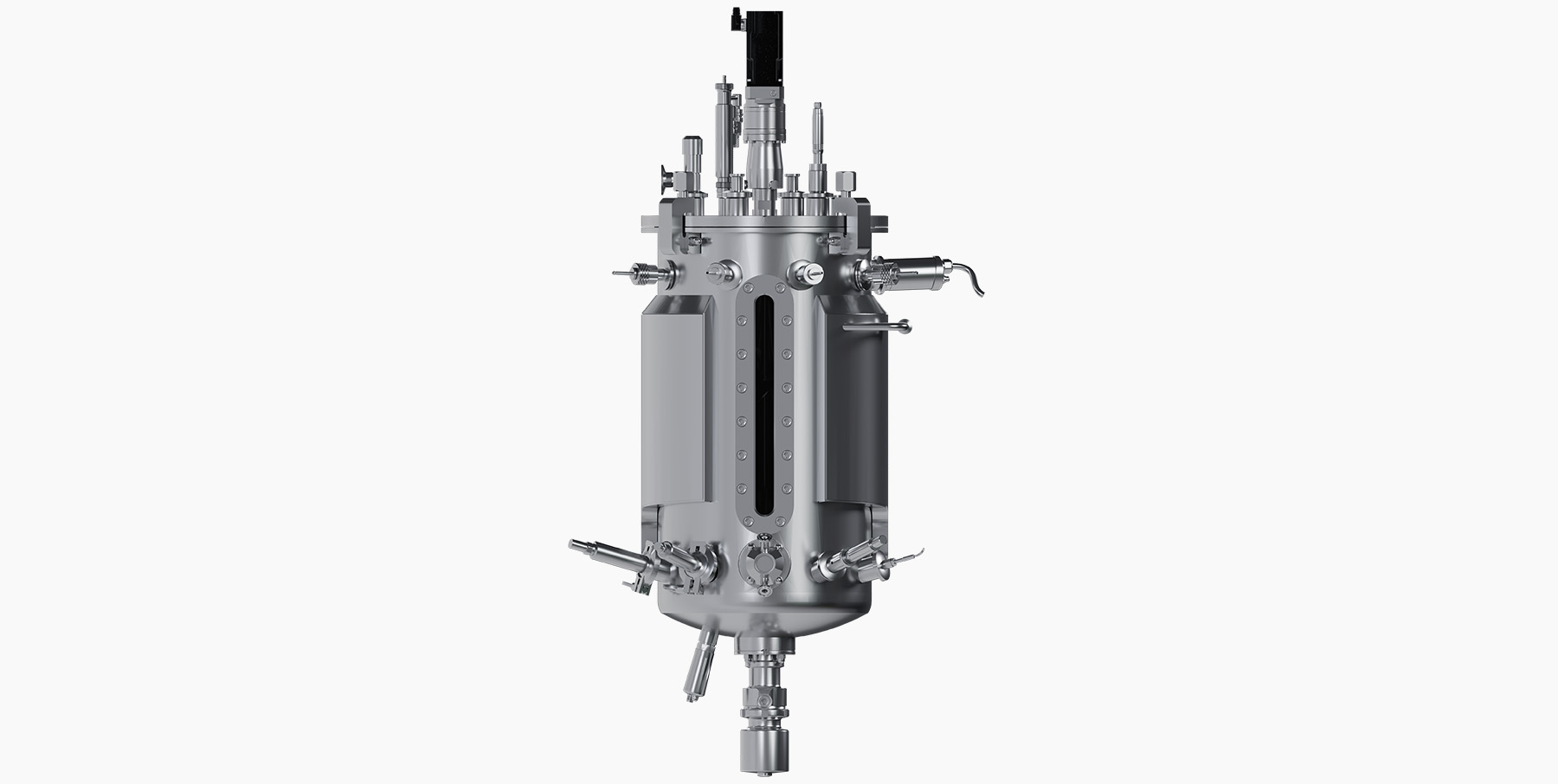

Key components include: external jacket, sparger, overlay gas inlets, rupture disc, addition valves, and ports for sensors, sampling kit, a bottom valve and a front-integrated sight glass allows monitoring of crucial parameters like turbidity and agitation.

Vessels for Cell Culture

The cellular version of our ePILOT Bioreactor is an advanced system designed to optimize cell culture, offering unprecedented flexibility and efficiency for cellular applications. With working volumes of 10, 20, 30, and 50 liters and interchangeable vessels, the ePILOT seamlessly adapts to diverse research, development, and production needs.

This configuration encompasses comprehensive control of critical parameters vital for optimal cellular growth, including pH, temperature, dissolved oxygen, and foam. The jacketed vessel, available in a double-wall option, is equipped with a 2x pitched-blade impeller, its agitation features precisely governed by a Servomotor.

Additionally, to further elevate functionality, the system can be augmented with optional features such as a microsparger for finer bubble generation and an AUTO SIP version for autonomous sterilization.

Vessels for Microbial Culture

The microbial version of our ePILOT bioreactor boosts the efficiency and flexibility of microbial fermentation processes. It ensures optimal growth conditions and process control for microbial applications.

Equipped with interchangeable vessels, the pilot scale microbial bioreactor easily adapts to various scales, from small-scale research to larger production batches. Its advanced control systems and precise monitoring capabilities enable meticulous management of fermentation parameters, assuring high-quality outcomes.

It features a jacketed vessel and includes a Servomotor that controls three 6-blade Rushton impellers, providing superior mixing and aeration essential for effective microbial growth and product formation.

The system can be upgraded with options like a microsparger for finer bubble generation, a dip pipe sparger for efficient gas delivery, AUTO SIP version, and off-gas analysis to fine-tune the cultivation environment.

Our sales team is ready to assist you with the most technical details

Connect with our team today. Whether you have specific questions or are just beginning to explore, we're here to guide and assist.