Advanced laboratory filtration

Leading laboratory filtration technology for the most demanding downstream processes

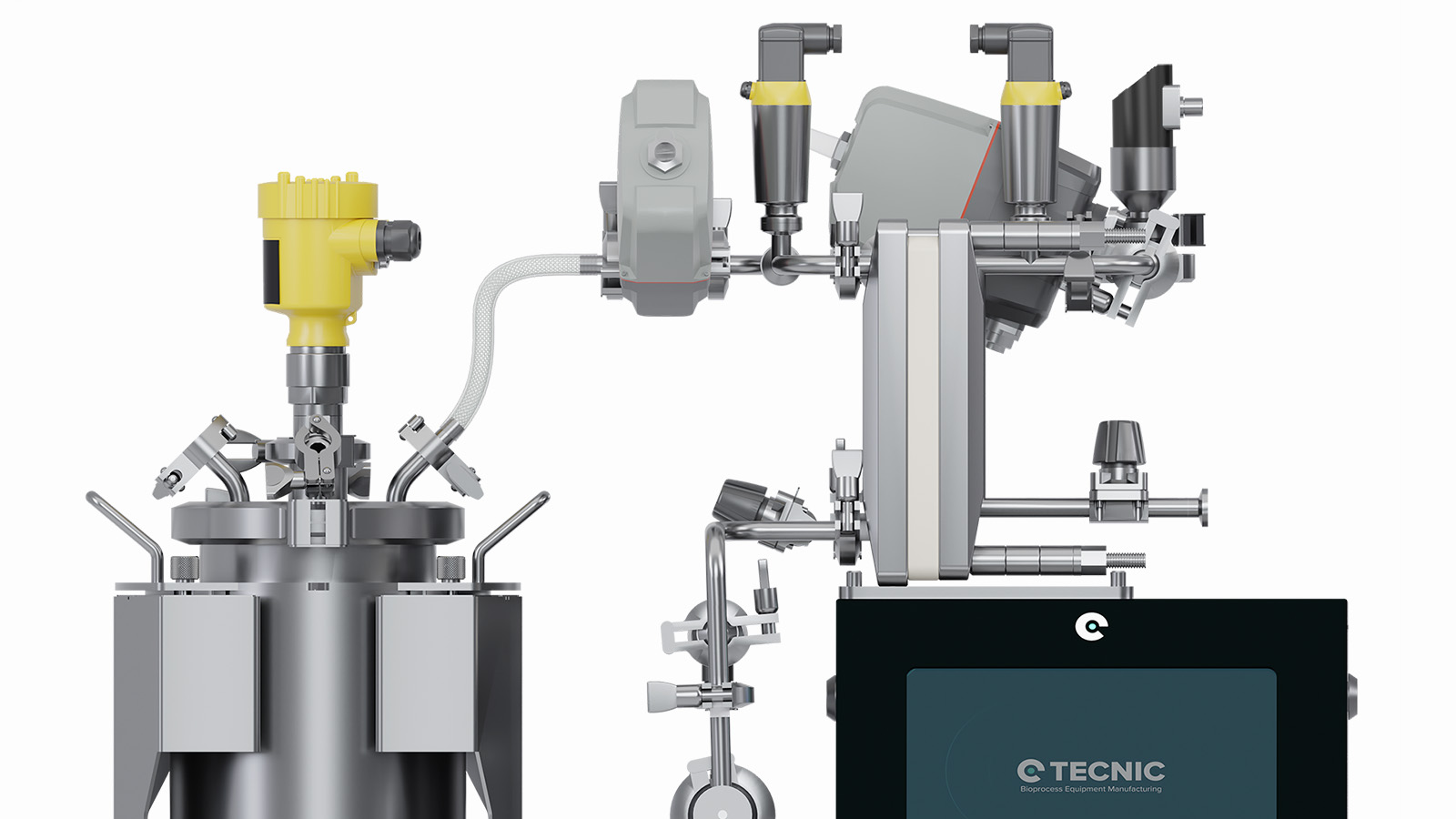

High-performance automatic tangential flow filtration laboratory system for superior results, an excellent choice for research, development and small production purification.

Engineered to meet the exacting standards of biotechnological downstream processes, the eLAB TFF fully automatic systems stand out for their exceptional filtration performance, reaching a maximum of 0.5 m² of total membrane surface area. This achievement ensures unparalleled throughput and efficiency during continuous operations, facilitated by a meticulously designed tangential flow filter that minimizes membrane clogging and fouling. Notably, the system is particularly well-suited for concentration tasks involving proteins or antibodies.

The core of the system lies in its central control module, powered by an industrial-grade PLC, providing precise control over operations to diafiltrate and concentrate the product. Complemented by a robust stainless-steel vessel and advanced sensors, the system guarantees a stable and reliable filtration process.

The tangential filter enables fluid to move parallel to the filter, allowing smaller components to pass through while retaining larger ones. With an impressive filtration capacity of up to 0.5 m², it ensures optimal performance. The tank, meticulously crafted from 316L stainless steel, is available in volumes of 5L or 10L, featuring five ports catering to diverse functionalities.

The integrated control unit seamlessly incorporates TECNIC's proprietary eSCADA system, additional pumps, and an aeration system. Enhance your laboratory filtration processes with the precision and innovation of the eLAB® TFF, setting a new standard for professional biotech applications.

Advanced control and customization in laboratory filtration

Models - Cassette and Hollow Fiber

TECNIC eLAB TFF system is adeptly equipped for precise applications with its membrane cassette configuration. This setup is designed for optimal performance in tangential flow filtration laboratory processes, accommodating a range of membrane surface areas up to 0.5 m². The cassette configuration is particularly suitable for applications requiring high throughput combined with sensitivity for quality retention of biomolecules. It features low shear stress on cells and proteins, ensuring the integrity of delicate samples during concentration and diafiltration processes. The system's flexibility is further enhanced by the inclusion of a low-shear, four-piston diaphragm pump, tailored to meet the sophisticated needs of precise laboratory filtration and separation tasks.

For processes necessitating high surface-area-to-volume ratios, the eLAB TFF system's hollow fiber configuration offers an exceptional solution. It leverages the advantages of hollow fibers, which are ideal for high-efficiency separation and purification tasks, to provide superior laboratory filtration performance. This configuration is engineered to support a membrane surface area ranging from 0.1 to 0.4 m², catering to a variety of scaling requirements. The hollow fiber setup is especially beneficial for its high packing density and low hold-up volume, making it a perfect match for applications that demand both precision and economy in the use of consumables and samples.

Cassette

Discover eLAB TFF Cassette for

Advanced Ultrafiltration Technology

Hollow Fiber

And ceramics, for laboratory filtration processes that require maximum longevity and durability

Our TFF system exemplifies advanced engineering and automation in tangential flow filtration for laboratory. A key feature of this system is the incorporation of high-precision proportional valves, which are crucial for the refined control of laboratory filtration parameters. Operating on principles of proportional control, these valves allow for fine and dynamic adjustments in the regulation of flow, diferential pressure and transmembrane pressure, essential for maintaining process integrity and product quality.

The ability of these valves to respond to minimal variations in system conditions enables precise regulation of flow and pressure. This is particularly important in applications requiring selective separation and high product recovery, such as in the biopharmaceutical and biotechnology industries. Precision in flow and pressure control ensures efficient system operation, minimizing concentration polarization and membrane fouling, thereby enhancing laboratory filtration efficiency and extending membrane lifespan.

In addition, the eLAB TFF system takes an automated approach to managing these parameters, significantly reducing the need for manual intervention and increasing process reproducibility. This automation is achieved through an industrial programmable logic controller (PLC) and an intuitive human-machine interface, allowing operators to monitor and adjust filtration parameters in real-time.

Advanced automation with proportional valves

100% Efficiency and Precision

Our eLAB Tangential Flow Filtration for laboratory is engineered to excel in key aspects of filtration: differential pressure, transmembrane pressure, and flow rate, ensuring unparalleled efficiency and precision in laboratory processes.