Filtration is an essential technique in biotechnology, used to separate solids from liquids, clarify solutions and purify biological products. Various filtration systems exist, each suitable for specific applications. In the following, we will explore the most commonly used filtration systems in biotechnology.

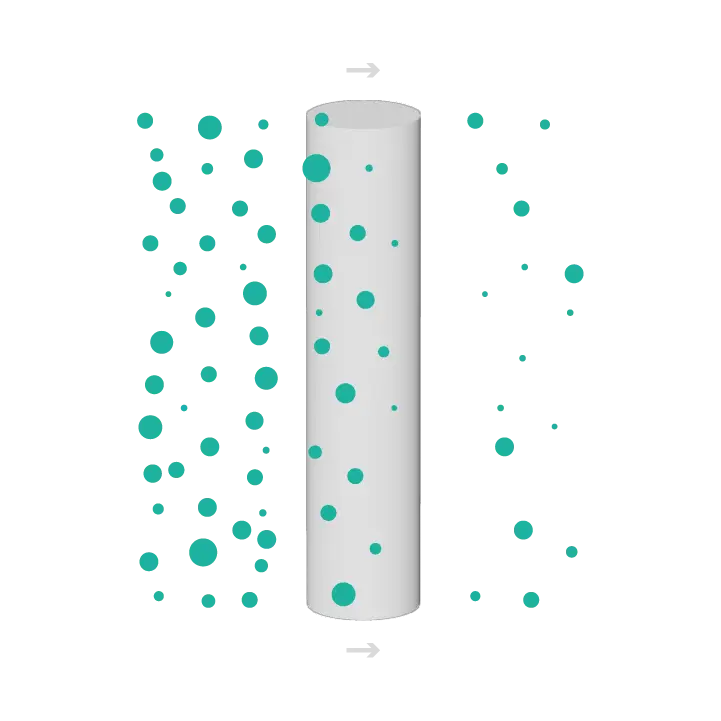

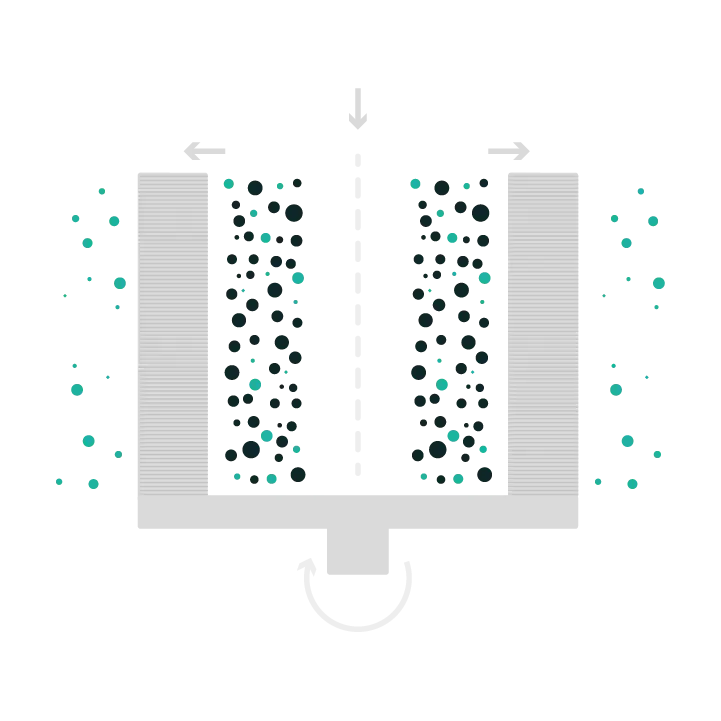

Tangential flow filtration

Filtration is an essential technique in biotechnology, used to separate solids from liquids, clarify solutions and purify biological products. Various filtration systems exist, each suitable for specific applications. In the following, we will explore the most commonly used filtration systems in biotechnology ⇀.

Applications

- Protein purification: Used for protein concentration and desalting.

- Fermentate clarification: Removes cells and other residues from cultures of microorganisms.

- Concentration of biomolecules: Suitable for the concentration of antibodies, enzymes and other biological products.

Advantages

High efficiency: Allows large volumes to be processed with high separation efficiency.

Reduced debris: Flow orientation helps to reduce debris build-up on the filter surface.

Versatility: Can be adjusted for different applications by changing parameters such as pressure and membrane type.

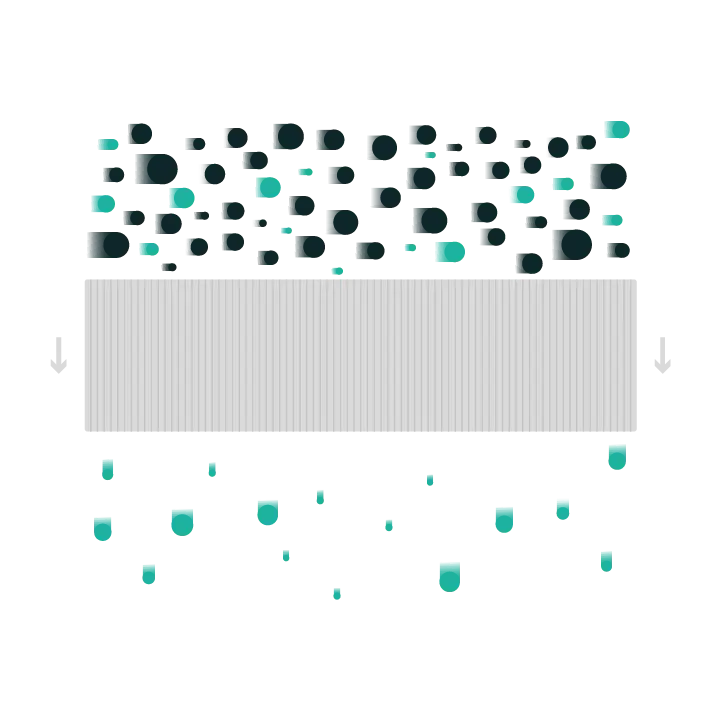

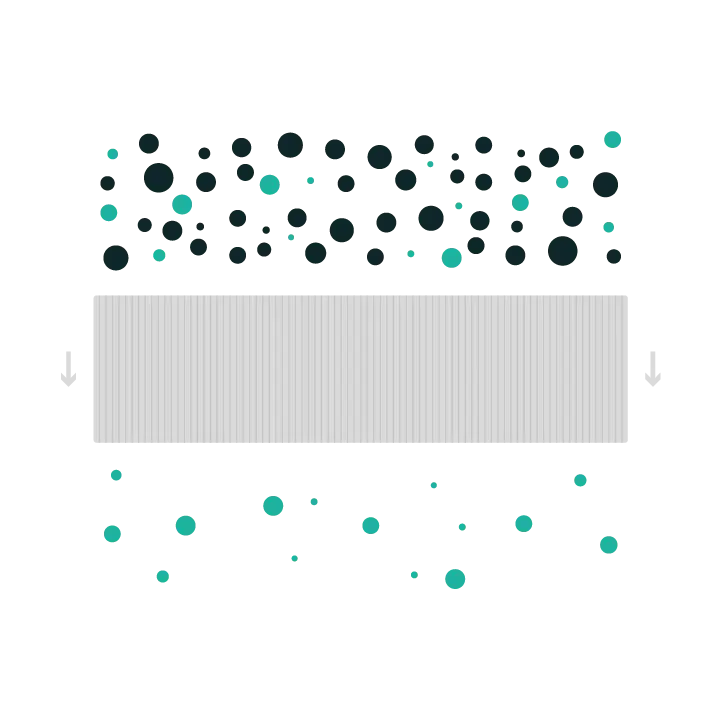

Depth filtration

Depth filtration uses a three-dimensional porous media that retains particles through the entire thickness of the filter. This type of filtration is suitable for applications where high particle holding capacity is required.

Applications

Liquid clarification: Used in the production of beverages and pharmaceuticals.

Protection of final filtration systems: Acts as a preliminary stage to prolong the life of membrane filters.

Advantages

High retention capacity: Capable of retaining large quantities of particles.

Long service life: The three-dimensional structure of the filter allows prolonged use without the need for frequent changes.

Membrane filtration

Membrane filtration uses a semi-permeable barrier to separate particles and solutes from a liquid. There are several types of membrane filtration, including microfiltration, ultrafiltration, nanofiltration and reverse osmosis, each suitable for different particle and solute sizes.

Applications

Microfiltration: Retains particles and microorganisms. Applied in the clarification of liquids and sterilisation of solutions.

Ultrafiltration: Retains macromolecules such as proteins and polysaccharides. Used in the concentration and desalination of biological solutions.

Nanofiltration: Retains low molecular weight solutes and some ions. Applied in desalination and water purification.

Reverse osmosis: Retains ions and small molecules. Used in water purification and ultrapure water production.

Advantages

High selectivity: Allows precise separation of specific particles and solutes.

Wide range of applications: Suitable for processes from clarification to purification and concentration of biological products.

Centrifugal filtration

Centrifugal filtration uses centrifugal force to separate particles from a solution. This type of filtration is especially useful for the separation of cells and other components of biological cultures.

Applications

Cell separation: Used in the collection of cells from bacterial, yeast and mammalian cell cultures.

Clarification of suspensions: Suitable for clarification of solutions with high solids loading.

Advantages

Fast and efficient: Enables fast and efficient particle separation.

Versatility: Suitable for a wide range of biological applications.

Final considerations

The selection of the appropriate filtration system depends on several factors, including the type of solution, the size of the particles to be separated, and the specific requirements of the process. Each filtration system has its own advantages and limitations, and the combination of different techniques may be necessary to achieve the desired results in complex biotechnological processes.

Conclusion

Filtration systems play a crucial role in biotechnology, facilitating the separation and purification of biological products. From cross-flow filtration to centrifugal filtration, each method offers unique solutions to various challenges in the production and purification of biomolecules. Understanding and correctly implementing these technologies is essential for success in modern biotechnology.

Frequently Asked Questions (FAQ)

Filtration systems are equipment designed to separate, purify and concentrate biomolecules and other biological components. These systems are crucial for the processing of biotechnological products, ensuring their purity and quality.

Tangential flow filtration (TFF) is a technique where the liquid flow is parallel to the filter surface, allowing the separation of components without clogging the filter.

There are several types, including tangential flow filtration, centrifugal filtration, membrane filtration and depth filtration.

They are used in the production of vaccines, antibodies, recombinant proteins, fermentation and clarification of cell cultures, among others.

They offer high efficiency, scalability and flexibility, maximising product recovery, reducing processing time and ensuring consistency and quality of the final product.