Single-use technology has been one of the most influential developments in the biopharmaceutical industry, which has undergone significant structural transformations in recent decades. The implementation of single-use bioreactors, filtration systems, and bags has introduced substantial operational advantages, such as greater flexibility, reduced cross-contamination, and optimized operational costs. However, this technological evolution has raised environmental concerns, particularly regarding plastic waste management and long-term sustainability.

The controversy surrounding the sustainability of these systems has sparked a polarized debate within the scientific and industrial communities. While some experts argue that the use of polymers in these devices presents a significant ecological challenge, others maintain that eliminating resource-intensive processes, such as cleaning and sterilization, offsets the overall environmental footprint of SUT. This article critically examines this issue, using a life-cycle approach to compare the environmental efficiency of Single-Use systems versus reusable stainless-steel systems.

Evaluation of single-use technology: Benefits and limitations

Single-Use systems have been widely adopted due to a series of tangible benefits that have redefined biotechnological processes:

Reduction of cross-contamination: Eliminating the need for on-site cleaning minimizes contamination risks, which is crucial in the production of highly sensitive biological products.

Flexibility and scalability: These systems facilitate the transition between different production lines without prolonged downtime, optimizing the manufacturing of personalized therapies and small batches.

Operational cost optimization: The elimination of expenses related to water, chemicals, and energy associated with cleaning and validation of reusable equipment.

Implementation efficiency: The installation and commissioning of these systems are faster and require less specialized infrastructure than traditional systems.

Despite these benefits, the primary objection revolves around plastic waste generation and its impact on the environmental footprint.

Comparative analysis of environmental impact: Single-use systems vs. reusable systems

To fully understand the environmental impact of Single-Use systems, it is essential to analyze their life cycle compared to conventional reusable systems.

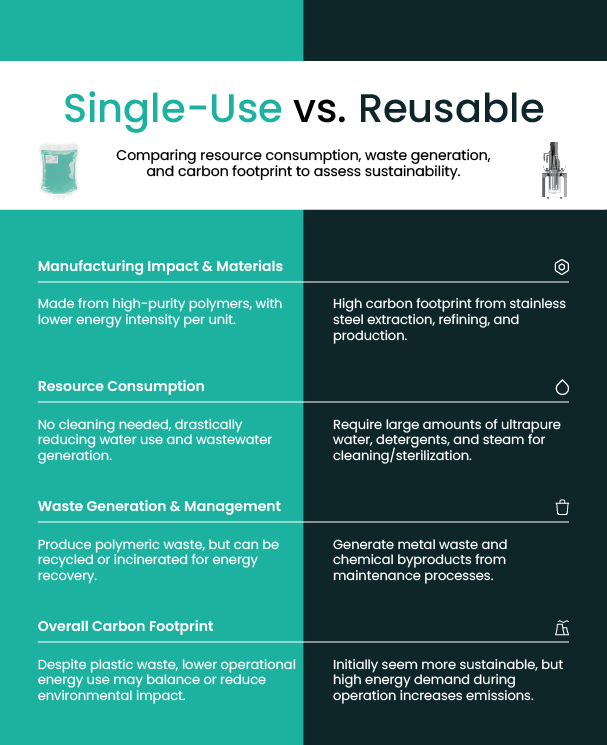

1. Manufacturing impact and materials used

Reusable systems require an initial investment in stainless steel, whose production entails a high carbon footprint due to metal extraction, refining, and manufacturing.

In contrast, Single-Use systems are made from high-purity polymers, whose production also generates emissions but with lower energy intensity per unit of product.

2. Resource consumption during use

Cleaning and sterilization of reusable equipment require large volumes of ultrapure water, specialized detergents, and steam, generating difficult-to-treat effluents.

Single-Use systems eliminate the need for these procedures, drastically reducing water consumption and the generation of contaminated wastewater.

3. Waste generation and mitigation strategies

Stainless steel equipment requires continuous maintenance and eventual replacement, generating metal waste and chemical byproducts from maintenance processes.

In contrast, Single-Use systems generate solid polymeric waste, which can be recycled or managed through energy recovery incineration. Studies indicate that this practice can offset a significant portion of the environmental impact of plastics used in bioprocesses.

4. Overall carbon footprint

- Life cycle analyses have demonstrated that although reusable systems may initially seem more sustainable, their high energy demand during the operational phase can exceed the accumulated carbon footprint of Single-Use systems.

Emerging strategies for sustainability in single-use technology

As the adoption of Single-Use Technologies (SUT) expands, the industry has developed innovative approaches to mitigate their environmental impact:

Advanced polymer recycling: Recycling programs have been implemented in which plastics used in bioprocesses are reprocessed for secondary industrial applications. Research efforts are also exploring chemical recycling methods, which can break down polymers into their monomeric components for repurposing in high-quality applications.

Energy recovery incineration: The energy valorization of plastic waste reduces dependence on fossil fuels by converting waste into heat and electricity sources. Advanced incineration facilities are being developed to maximize energy efficiency and minimize emissions, incorporating carbon capture technologies to further lower the environmental footprint.

Development of biodegradable materials: Recent research explores the feasibility of bioplastics with controlled decomposition for bioprocessing applications. Innovations in polymer chemistry have led to the development of hybrid materials that combine biodegradability with the necessary mechanical and chemical resistance required in bioprocess environments.

Reduction of polymer volume used: Design improvements have allowed material optimization to decrease plastic usage without compromising the structural integrity of systems. Computational simulations and AI-driven modeling are being leveraged to create thinner, stronger materials that maintain functionality while reducing overall polymer consumption.

Carbon footprint compensation: Leading biotechnology companies have begun integrating offset strategies, investing in reforestation initiatives and renewable energy projects. Some firms are also participating in closed-loop recycling systems, ensuring that used Single-Use components are repurposed within the industry, reducing dependency on virgin plastic production.

Conclusion

The paradigm that Single-Use Technology is environmentally unsustainable lacks a holistic analysis of these systems' life cycle. While polymer use presents a challenge, the benefits derived from reduced water and energy consumption and minimized cross-contamination risks position SUT as an environmentally viable alternative within the biopharmaceutical production spectrum.

Furthermore, advances in recycling, new material development, and environmental mitigation strategies make it possible to optimize these systems' sustainability and align them with circular economy principles. The key to the future of biotechnology lies in developing innovative solutions that maximize operational efficiency without compromising ecological balance.

For companies like TECNIC, the commitment to sustainability must be accompanied by a strategic approach based on innovation and continuous improvement. Integrating more efficient processes and a firm commitment to reducing the environmental footprint will be crucial differentiating factors in an ever-evolving sector. Sustainability in biotechnology should not be seen as a dichotomy but rather as a dynamic process of adaptation and optimization.

Frequently Asked Questions (FAQ)

They reduce water, energy, and chemical consumption by eliminating cleaning and sterilization.

It can be recycled, incinerated for energy, or minimized through biodegradable materials.

Lifecycle analyses show that despite plastic use, reduced energy and water consumption can balance overall emissions.

Advanced polymer recycling, energy recovery incineration, material reduction, and hybrid system adoption help minimize waste.

Stainless steel requires extensive water, chemicals, and energy for cleaning, while SUT eliminates these resource-intensive processes.

Sources of Information

Pietrzykowski, M., Flanagan, W., Pizzi, V., Brown, A., Sinclair, A., & Monge, M. (2013). An environmental life cycle assessment comparison of single-use and conventional process technology for the production of monoclonal antibodies. Journal of Cleaner Production, 41, 150-162.

Tan, Y., Wen, Z., Hu, Y., Zeng, X., Kosajan, V., Yin, G., & Zhang, T. (2023). Single-use plastic bag alternatives result in higher environmental impacts: Multi-regional analysis in country with uneven waste management. Waste Management, 171, 281-291.

Schmaltz, E., Melvin, E. C., Diana, Z., Gunady, E. F., Rittschof, D., Somarelli, J. A., Virdin, J., & Dunphy-Daly, M. M. (2020). Plastic pollution solutions: Emerging technologies to prevent and collect marine plastic pollution. Environment International, 144, 106067.