Bag system for safe storage of bioprocessing material

Innovative and reliable single-use bag storage for the biotech sector

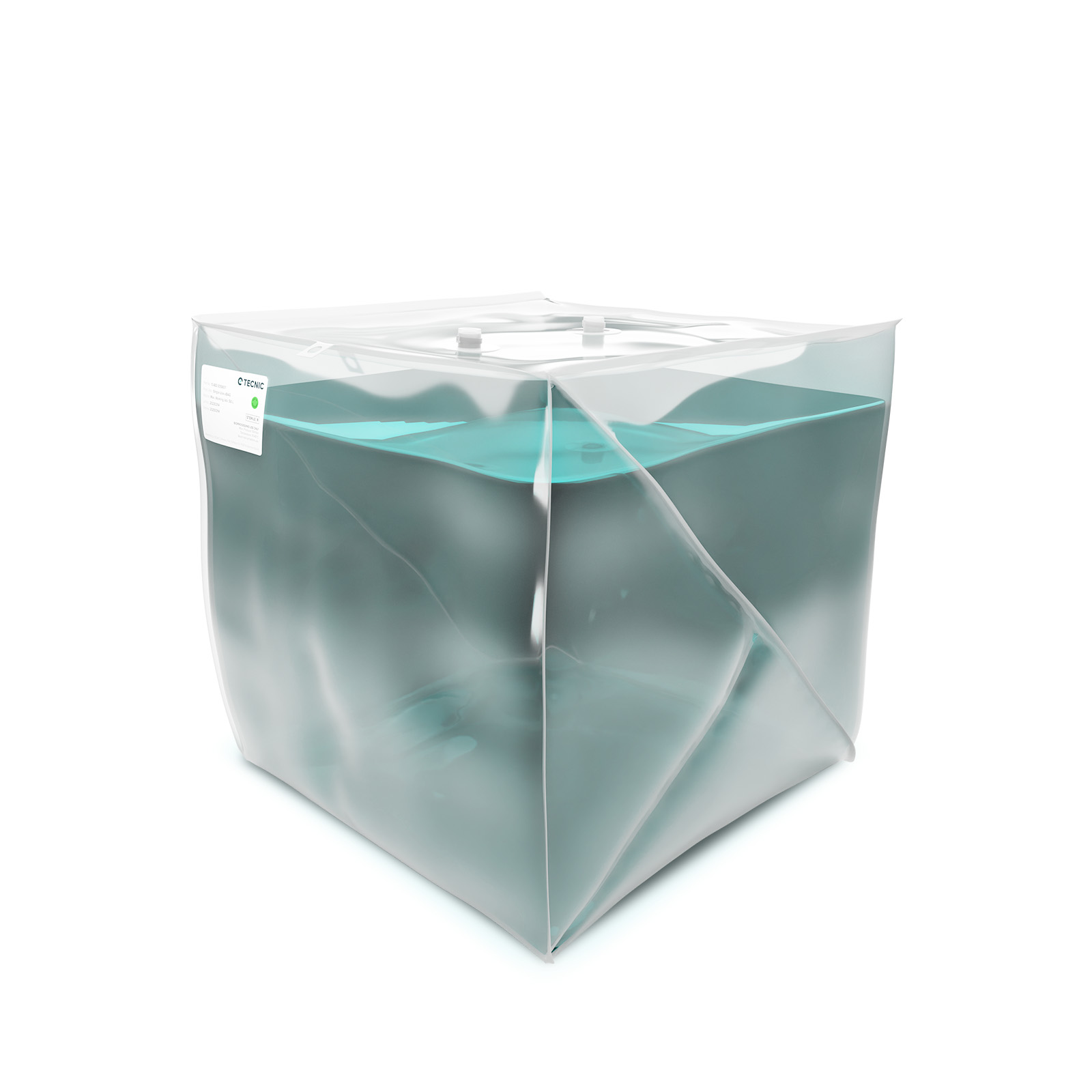

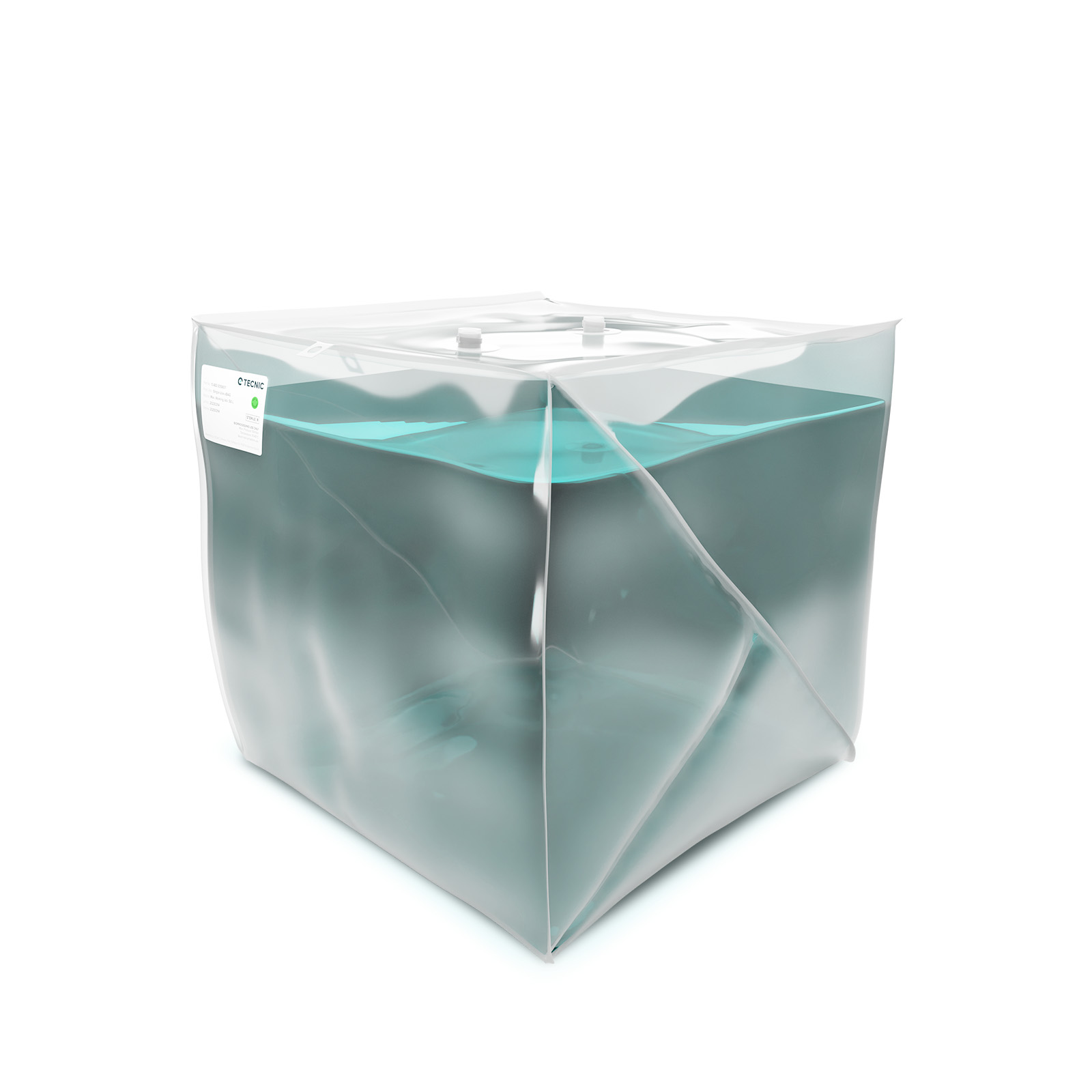

Single-use storage for biotech excellence with our eBAG 3D Storage

The single-use eBAG 3D Storage will optimize storage and easy transportation of liquids. Crafted from pharmaceutical-grade materials, this equipment can maintain the integrity of biologics, resist chemical degradation, and remain contaminant-free, which elevates your bioprocess endeavours with redefined functionality, style, durability and convenience.

Developed and Manufactured in TECNIC ISO7 Clean Room, eBAG 3D storage is built tough high-quality materials and undergo gamma irradiation. As a result, they are ready-to-use according the strictest pharmaceutical industry standards and available in various sizes (10L, 50L, 100L, 200L and 500L), designed fully compatible with our ePLUS® TANK ⇀. It can withstand rigorous handling to ensure safe containment of biopharmaceutical products. They also offer easy use with clear markings and ergonomic handles, which streamline manufacturing by easily connecting to existing systems for seamless integration into existing manufacturing processes.

Ensuring sterility and efficiency in bioprocess bag storage

Sterility assurance

Convenience and efficiency is equal to less downtime

Cost-effectiveness

Various configuration options

Effortlessly tailor the eBAG 3D Storage to accommodate diverse volumes by selecting the preferred number of ports. Our standard configuration options offer flexibility in terms of the number of ports, locations, and types, ranging from 3 ports to 4 ports. Each bag includes an inlet port, exhaust filter, and a harvest port.

Explore a spectrum of connectors and tubing options, such as Quick Couplers, Tri-Clamp (TC), Aseptic Connectors, C-Flex 374, and Luer Connectors. These choices ensure seamless integration, providing compatibility with your unique setup. Elevate your operational efficiency by embracing the versatility offered through these diverse configuration choices.

Bag scalability

Quality assurance

Film technology for enhanced bioprocess

Our TECNIC Film Technology is specifically engineered for high-quality. Every one of our Single-Use products distinguishes itself by its unique five-layer structure, with each layer serving a specific function to optimize the integrity, durability, longevity and the sterility of the equipment.

Layer 1 - LPDE (50μm)

Layer 2 - TIE (10μm)

Layer 3 - EVOH (20μm)

Layer 4 - TIE (10μm)

Layer 5 - ULPDE (230μm)

In-house ISO 7 cleanroom for single-use standards

The manufacturing process for our single-use bioprocessing products, such as the eBAG® 2D, 3D and SU vessel, strictly complies with the rigorous standards of an ISO 7 cleanroom This specific classification guarantees a highly controlled environment, characterized by a maximum particle count of 10,000 (≥ 0.5 μm) per cubic meter of air.

This level of control is critical for ensuring the sterility and quality of our products, as it significantly reduces the risk of microbial and particulate contamination. By adhering to these standards, we ensure that each product meets the high expectations of purity and performance required in sensitive bioprocessing applications, providing our clients with reliable and consistent biotechnological solutions.

High standards in bioprocessing

The eBAG® represents not just an innovation in cell culture film technology, but also sets new benchmarks in quality and regulatory compliance. Each eBAG® is manufactured under stringent Good Manufacturing Practices (GMP), ensuring that every product meets the highest standards of quality and safety.

Sterilization is a critical aspect of production. We employ advanced radiation sterilization methods, effectively eliminating biological contaminants without compromising the product's integrity. This sterilization process is crucial for maintaining sterility and safety in sensitive applications.

Furthermore, the production of eBAG® takes place in inhouse ISO 7 classified facilities. These cleanrooms are designed to control contamination and maintain an aseptic environment, essential for the manufacturing of biotechnological products. Adhering to ISO 7 standards ensures that each eBAG® is produced in a controlled environment, minimizing the risk of cross-contamination and ensuring product consistency.

Together, these quality measures and regulatory compliance reflect our commitment to excellence in manufacturing eBAG®, providing our clients with reliable and safe products for their critical bioprocessing applications.

Test | Requirements | Results |

USP <788> Particulate Matter in Injections | Pass | Pass |

USP <88> Systemic Toxicity | Pass | Pass |

USP <88> Intracutaneous | Pass | Pass |

USP <88> Implantation | Pass | Pass |

USP <87> Cytotoxicity, Agar Diffusion | Pass | Pass |

USP <87> Cytotoxicity, Elution | Pass | Pass |

USP <85> Kinetic-Chromogenic LAL | 0,25 EU/ml | 0,006 EU/ml |

USP <661.1> Physicochemical-Non Volatile | 15 mg | 1 mg |

USP <661.1> Physicochemical-Residue on Ignition | 5 mg | 1 mg |

USP <661.1>Physicochemical-Heavy Metals | 1 ppm | 1 ppm |

USP ≤661.1>Physicochemical-Buffering Capacity | 10 ml | 1 ml |

ISO 10993-4 In-Vitro Hemolysis Study | Non-haemolytic | Non-haemolytic |

Irradiation Dosage | 25-50 kGy | 25-50 kGy |

EP <3.2.2.1> Plastic Containers for Aqueous Solutions for Parenteral Infusion | Pass | Pass |

The eBAG® represents not just an innovation in cell culture film technology, but also sets new benchmarks in quality and regulatory compliance. Each eBAG® is manufactured under stringent Good Manufacturing Practices (GMP), ensuring that every product meets the highest standards of quality and safety.

Sterilization is a critical aspect of production. We employ advanced radiation sterilization methods, effectively eliminating biological contaminants without compromising the product's integrity. This sterilization process is crucial for maintaining sterility and safety in sensitive applications.

Furthermore, the production of eBAG® takes place in inhouse ISO 7 classified facilities. These cleanrooms are designed to control contamination and maintain an aseptic environment, essential for the manufacturing of biotechnological products. Adhering to ISO 7 standards ensures that each eBAG® is produced in a controlled environment, minimizing the risk of cross-contamination and ensuring product consistency.

Together, these quality measures and regulatory compliance reflect our commitment to excellence in manufacturing eBAG®, providing our clients with reliable and safe products for their critical bioprocessing applications.

Test | Need | Result |

USP <788> Particulate Matter in Injections | Pass | Pass |

USP <88> Systemic Toxicity | Pass | Pass |

USP <88> Intracutaneous | Pass | Pass |

USP <88> Implantation | Pass | Pass |

USP <87> Cytotoxicity, Agar Diffusion | Pass | Pass |

USP <87> Cytotoxicity, Elution | Pass | Pass |

USP <85> Kinetic-Chromogenic LAL | 0,25 EU/ml | 0,006 EU/ml |

USP <661.1> Physicochemical-Non Volatile | 15 mg | 1 mg |

USP <661.1> Physicochemical-Residue on Ignition | 5 mg | 1 mg |

USP <661.1>Physicochemical-Heavy Metals | 1 ppm | 1 ppm |

USP ≤661.1>Physicochemical-Buffering Capacity | 10 ml | 1 ml |

ISO 10993-4 In-Vitro Hemolysis Study | Non-haemolytic | Non-haemolytic |

Irradiation Dosage | 25-50 kGy | 25-50 kGy |

EP <3.2.2.1> Plastic Containers for Aqueous Solutions for Parenteral Infusion | Pass | Pass |

Bag properties

Robust exterior layer

Sterile environment

- > 25 kGy, not validated sterile

- Professional option with validated sterilization and a 2-year shelf life

This flexibility in sterilization options ensures that all our products can meet diverse sterility requirements of our customers.

Temperature Resilience

GMP and ISO standards

High Standards in Bioprocessing

The eBAG represents not just an innovation in cell culture film technology, but also sets new benchmarks in quality and regulatory compliance. Each eBAG is manufactured under stringent Good Manufacturing Practices (GMP), ensuring that every product meets the highest standards of quality and safety.

Sterilization is a critical aspect of production. We employ advanced radiation sterilization methods, effectively eliminating biological contaminants without compromising the product's integrity. This sterilization process is crucial for maintaining sterility and safety in sensitive applications.

Furthermore, the production of eBAG takes place in inhouse ISO 7 classified facilities. These cleanrooms are designed to control contamination and maintain an aseptic environment, essential for the manufacturing of biotechnological products. Adhering to ISO 7 standards ensures that each eBAG is produced in a controlled environment, minimizing the risk of cross-contamination and ensuring product consistency.

Together, these quality measures and regulatory compliance reflect our commitment to excellence in manufacturing eBAG, providing our clients with reliable and safe products for their critical bioprocessing applications.

Test | Requirements | Results |

USP <788> Particulate Matter in Injections | Pass | Pass |

USP <88> Systemic Toxicity | Pass | Pass |

USP <88> Intracutaneous | Pass | Pass |

USP <88> Implantation | Pass | Pass |

USP <87> Cytotoxicity, Agar Diffusion | Pass | Pass |

USP <87> Cytotoxicity, Elution | Pass | Pass |

USP <85> Kinetic-Chromogenic LAL | 0,25 EU/ml | 0,006 EU/ml |

USP <661.1> Physicochemical-Non Volatile | 15 mg | 1 mg |

USP <661.1> Physicochemical-Residue on Ignition | 5 mg | 1 mg |

USP <661.1>Physicochemical-Heavy Metals | 1 ppm | 1 ppm |

USP ≤661.1>Physicochemical-Buffering Capacity | 10 ml | 1 ml |

ISO 10993-4 In-Vitro Hemolysis Study | Non-haemolytic | Non-haemolytic |

Irradiation Dosage | 25-50 kGy | 25-50 kGy |

EP <3.2.2.1> Plastic Containers for Aqueous Solutions for Parenteral Infusion | Pass | Pass |

The eBAG® represents not just an innovation in cell culture film technology, but also sets new benchmarks in quality and regulatory compliance. Each eBAG® is manufactured under stringent Good Manufacturing Practices (GMP), ensuring that every product meets the highest standards of quality and safety.

Sterilization is a critical aspect of production. We employ advanced radiation sterilization methods, effectively eliminating biological contaminants without compromising the product's integrity. This sterilization process is crucial for maintaining sterility and safety in sensitive applications.

Furthermore, the production of eBAG® takes place in inhouse ISO 7 classified facilities. These cleanrooms are designed to control contamination and maintain an aseptic environment, essential for the manufacturing of biotechnological products. Adhering to ISO 7 standards ensures that each eBAG® is produced in a controlled environment, minimizing the risk of cross-contamination and ensuring product consistency.

Together, these quality measures and regulatory compliance reflect our commitment to excellence in manufacturing eBAG®, providing our clients with reliable and safe products for their critical bioprocessing applications.

Test | Requirements | Results |

USP <788> Particulate Matter in Injections | Pass | Pass |

USP <88> Systemic Toxicity | Pass | Pass |

USP <88> Intracutaneous | Pass | Pass |

USP <88> Implantation | Pass | Pass |

USP <87> Cytotoxicity, Agar Diffusion | Pass | Pass |

USP <87> Cytotoxicity, Elution | Pass | Pass |

USP <85> Kinetic-Chromogenic LAL | 0,25 EU/ml | 0,006 EU/ml |

USP <661.1> Physicochemical-Non Volatile | 15 mg | 1 mg |

USP <661.1> Physicochemical-Residue on Ignition | 5 mg | 1 mg |

USP <661.1>Physicochemical-Heavy Metals | 1 ppm | 1 ppm |

USP ≤661.1>Physicochemical-Buffering Capacity | 10 ml | 1 ml |

ISO 10993-4 In-Vitro Hemolysis Study | Non-haemolytic | Non-haemolytic |

Irradiation Dosage | 25-50 kGy | 25-50 kGy |

EP <3.2.2.1> Plastic Containers for Aqueous Solutions for Parenteral Infusion | Pass | Pass |

Bag properties

Robust exterior layer

Sterile environment

- > 25 kGy, not validated sterile

- Professional option with validated sterilization and a 2-year shelf life

This flexibility in sterilization options ensures that all our products can meet diverse sterility requirements of our customers.

Temperature Resilience

GMP and ISO standards

Our sales team is ready to assist you with the most technical details.

Connect with our team today. Whether you have specific questions or are just beginning to explore, we're here to guide and assist. Reach out now and let's shape the future together.