TECNIC Introduces eLAB® Essential Bioreactor

TECNIC is proud to announce the launch of the eLAB® Essential bioreactor, our latest addition to our catalogue of biotechnology solutions. Carefully designed to combine simplicity with innovation, the eLAB® Essential symbolises our ongoing commitment to advancing biotech research and production.

Some technical specifications of the Essential

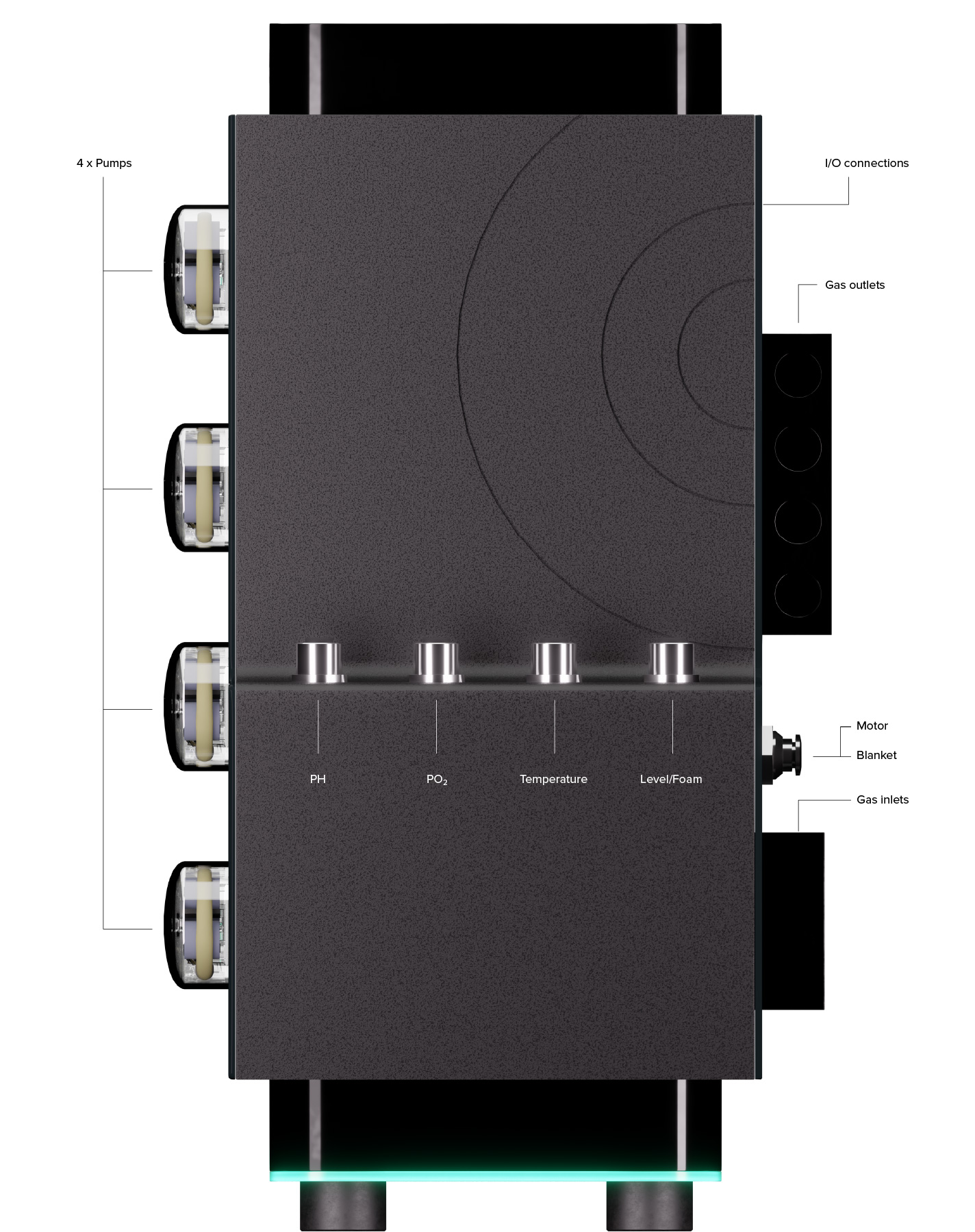

Compact and easy to use, this system offers hassle-free operation, allowing professionals to concentrate on their research or production without distraction. Its lightweight design, weighing less than 5 kg and only 20 cm wide, maximises laboratory space efficiency and ensures that functionality is not sacrificed for convenience.

The foundation of the eLAB® Essential is the eOS® operating system, an intuitive interface that simplifies the management of critical parameters to ensure optimal results across a wide range of biotech applications. From pH and temperature control to agitation, foam and pO2, every aspect is managed with precision, reflecting our focus on providing tools that not only meet but exceed user expectations.

Versatile support for a range of applications

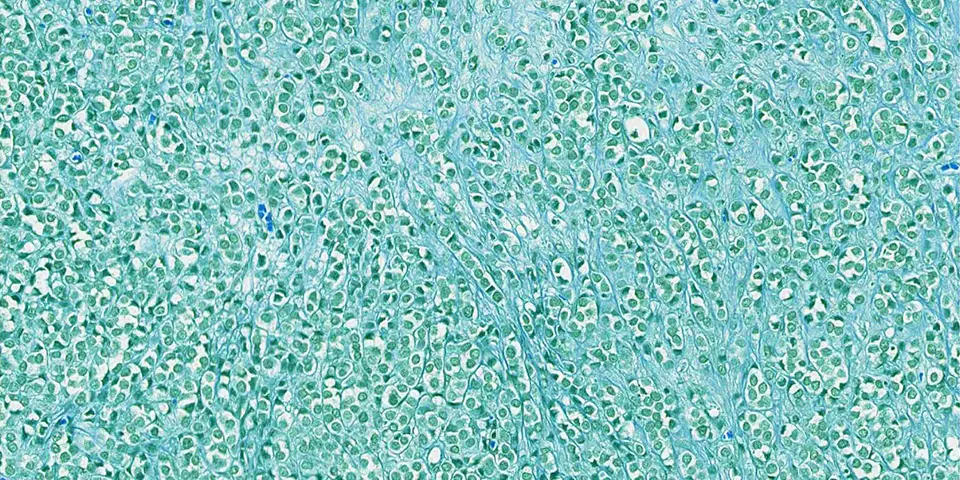

Equipped with four multi-solution addition pumps, the eLAB® Essential supports a wide range of vessel volumes from 0.5L to 5L, offering unrivalled versatility for different bioprocessing needs. Whether for cell culture development, enzyme production or vaccine manufacturing, this bioreactor can adapt to any project specification, offering customised solutions to maximise efficiency and effectiveness.

TECNIC understands the importance of flexibility and adaptability in biotechnology. The eLAB® Essential Bioreactor is designed to be versatile, compatible with both single-use and multi-use vessels. This feature ensures that the eLAB® Essential can adapt to various laboratory environments and biotechnological processes, from research and development to small-scale production. Switching between single-use and multi-use vessels facilitates a seamless transition between different development and production phases. It also allows for greater resource management, economy, and efficiency. Single-use vessels are ideal for applications requiring sterile conditions without cleaning and sterilization complications. Multi-use vessels are perfect for repetitive and long-duration processes. This integrated solution ensures that the laboratory's needs are met.

Our commitment

At TECNIC, we are committed to innovation and supporting our customers. We offer solutions that not only meet but exceed expectations in the field of biotechnology. Our thoughtful design approach reflects this commitment.

The launch of the eLAB® Essential Bioreactor reaffirms our commitment to excellence and innovation. This milestone reflects our dedication to providing advanced solutions that meet the growing demands for precision, efficiency, and flexibility in the biotechnology sector. For pricing and availability details, please contact your local TECNIC representative.

We invite the scientific and production community to discover how eLAB® Essential ⇀ can transform their laboratories and significantly contribute to the realization of biotechnological projects with unprecedented efficiency and effectiveness.