TECNIC presents its new manufacturing plant for Single-Use elements

This facility is solely dedicated to the manufacturing of Single-Use elements, including bags, flow kits, and any necessary customization to meet the needs of our clients.

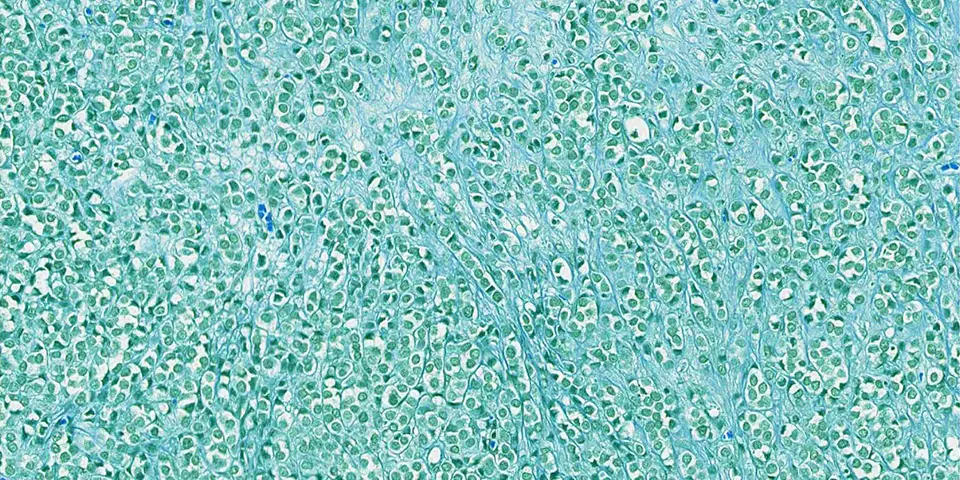

TECNIC is pleased to announce the opening of our new Single-Use plant, located within our facilities. This facility is solely dedicated to the manufacturing of Single-Use elements, including bags, flow kits, and any necessary customization to meet the needs of our clients. We take pride in offering a wide range of high-quality Single-Use products that not only meet but exceed our clients' expectations.

Advantages of single-use plant

Single-Use equipment ⇀ has become increasingly important in the biotech industry due to the numerous advantages they offer. This type of equipment allows for all stages of a bioprocess, from preparing culture media and necessary solutions to initiating a process, to cultivation, and subsequent product purification. One of the most significant advantages of Single-Use equipment is the reduction in installation and operating costs since there is no need for cleaning and sterilization cycles between processes. Additionally, the time required to verify cleanliness and sterility is minimized as these materials come pre-irradiated and with manufacturing and irradiation certification.

Single-Use technology also provides operational flexibility, allowing for quick transition from one process to another, regardless of the microorganism, in our single-use plant. This minimizes the risks of cross-contamination and helps streamline the entire process. Additionally, the smaller size of Single-Use equipment reduces the space required in production facilities, enabling more efficient use of available space in our single-use plant.

At TECNIC, we follow a comprehensive process philosophy designed to provide complete solutions to our clients' needs, leveraging our single-use plant's capabilities. This approach covers all stages of the process, from initial development and design to final delivery and support. Our comprehensive process begins with a deep understanding of our clients' needs, allowing us to tailor our solutions to their specific requirements. We work closely with our clients to develop a detailed project plan that incorporates all aspects of the biotech process, from initial design and development to final delivery and support, all facilitated through our single-use plant

Commitment to quality and safety

TECNIC not only focuses on the quality of our products but also on ensuring the safety of our facilities. Our new Single-Use plant is ISO 7 certified and has a HVAC system qualification report in the Single-Use production area, demonstrating our commitment to safety. Additionally, our bags have biological compatibility certifications 85, 87, 88, and 661.2, ensuring the highest quality of our products.

Once the project plan is established, we utilize our equipment and technology to carry out all phases of the biotech process. This includes preparing the necessary culture media and solutions, initiating the process, cultivating the product, and performing the final purification steps.

Throughout the entire process, we maintain a strict focus on quality and efficiency, ensuring that our solutions meet the highest standards of performance and reliability. Our team of experts is always available to provide continuous support and assistance, ensuring that our clients' needs are met and their operations run smoothly and effectively.

By following a comprehensive process philosophy and utilizing our new Single-Use plant, we can offer our clients a wide range of solutions tailored to their specific needs. Our commitment to innovation and quality ensures that our solutions are always at the forefront of the biotech industry, providing our clients with the best possible results and helping them achieve their goals in the most efficient and cost-effective manner possible.