The biotechnology industry is constantly evolving, and bioprocesses play a fundamental role in the development of biopharmaceutical products, cell therapies, and recombinant protein production. The trends in bioprocessing for 2025 focus on automation, scalability, digitalization, and the use of single-use systems, with an emphasis on sustainability and efficiency. Additionally, an even greater integration of advanced technologies is expected to enhance productivity and reduce operational costs at all stages of production.

This article will explore the most relevant trends in bioprocessing that are transforming the industry and how companies can adapt to improve their competitiveness, ensuring their place in an increasingly demanding market.

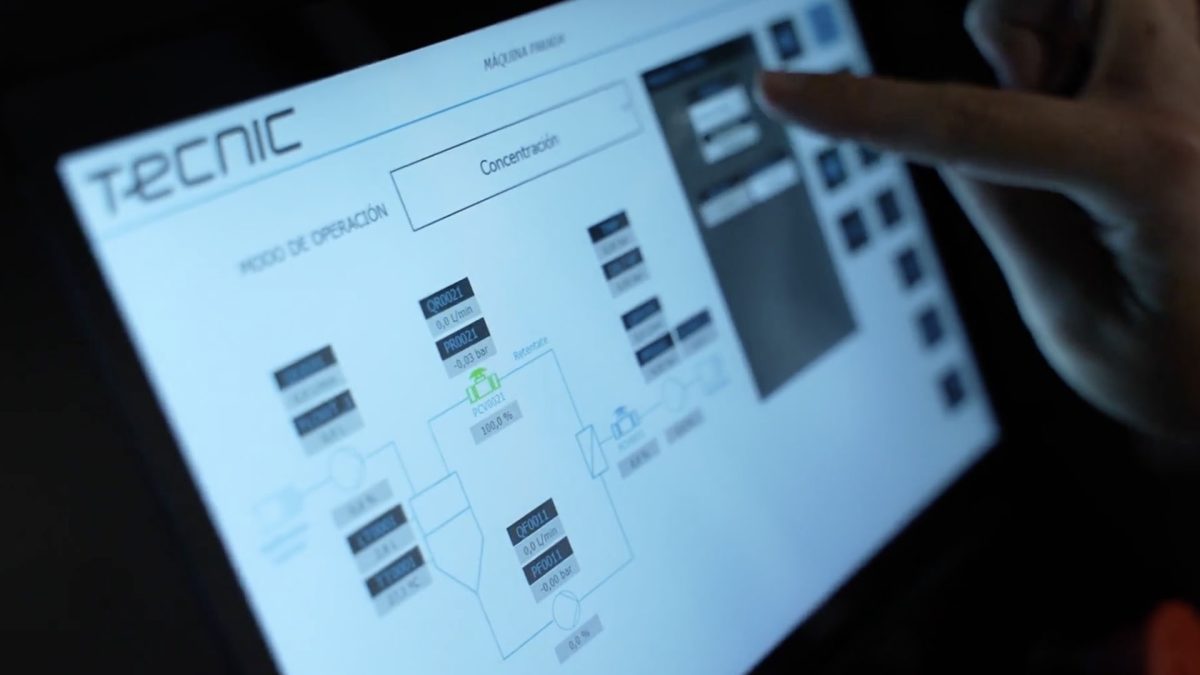

Automation and digitalization in bioprocessing

One of the biggest changes in the industry is the integration of advanced software and artificial intelligence (AI) to optimize real-time production. The trends in bioprocessing indicate that:

AI and machine learning will enable cell culture optimization and outcome prediction.

The use of digital twins will be enhanced to simulate bioprocesses and predict behaviors before applying them in real production.

Smart sensors in bioreactors will collect precise data, ensuring total process control.

Automation will reduce dependence on human intervention, allowing processes to become more efficient and reproducible.

These advances will facilitate the complete automation of bioprocesses, reducing variability and improving the final product quality. As more companies adopt these technologies, bioprocess efficiency will increase significantly.

Expansion of Single-Use Systems

The use of single-use bioreactors continues to grow due to their flexibility and operational efficiency. The trends in bioprocessing for 2025 confirm that these systems will be key for biopharmaceutical production for several reasons:

They eliminate the need for cleaning and reduce the risk of cross-contamination.

They are scalable, allowing a seamless transition from laboratory to industrial production without significant investments.

The industry is developing more sustainable materials to minimize the environmental impact of single-use waste.

Recycling strategies and partial reuse of components are being implemented to reduce the ecological footprint.

The flexibility of single-use systems makes them an attractive solution for the industry, enabling adaptation to different production scales. Leading companies are already adopting strategies to optimize these processes without compromising sustainability.

Scalability in Bioprocessing

Scalability is a key challenge in biomanufacturing. For 2025, the trends in bioprocessing point to the expansion of:

Perfusion systems, which allow continuous production and increase cell density.

Modular platforms, which facilitate scaling up without compromising process quality.

Hybrid systems (single-use + multi-use), optimizing costs and manufacturing flexibility.

Modular designs in bioprocessing, enabling faster adaptations to production changes without major interruptions.

These advances will make scalability more efficient, allowing companies to adapt their production to market needs. The ability to quickly adjust production volumes will be a key factor in the success of biopharmaceutical companies.

Sustainable and Efficient Production

Environmental regulations are driving the need for more sustainable bioprocesses. The trends in bioprocessing indicate that companies will aim to:

Reduce energy and water consumption in manufacturing.

Develop biodegradable and recyclable materials for single-use equipment.

Optimize waste management generated by bioprocesses.

Integrate renewable energy sources in production plants to lower the carbon footprint.

Implement circular economy models in the management of biotechnological inputs and waste.

The combination of sustainability and efficiency will be crucial for the industry to continue growing responsibly. Regulatory pressure and market demand are driving the adoption of more eco-friendly practices in global biomanufacturing.

Expansion of Advanced Therapies (ATMPs)

Advanced therapies (ATMPs), such as gene and cell therapies, are driving innovations in bioprocessing. The trends in bioprocessing for 2025 highlight:

Increased demand for closed and automated systems for cell therapy production.

Development of specialized bioreactors for cell expansion and the safe handling of genetic material.

Stricter regulations to ensure the safety and quality of these therapies.

New scalability strategies in cell therapy production to reduce costs and production time.

Adoption of advanced technologies to ensure product stability during storage and transport.

The biopharmaceutical industry is rapidly evolving to meet this growing demand for personalized, high-tech therapies. This sector’s growth is expected to drive investment in specialized infrastructure for ATMP production.

Conclusion

The trends in bioprocessing for 2025 are defined by automation, scalability, digitalization, sustainability, and the rise of advanced therapies. The adoption of these innovations will enable the biopharmaceutical industry to improve efficiency and competitiveness. As the demand for more efficient and sustainable bioprocesses increases, companies must be prepared to implement these technologies effectively.

At TECNIC, we offer advanced solutions such as single-use bioreactors, perfusion systems, and software for bioprocess optimization. If you want to learn more about how these technologies can improve your production, contact us and discover how we can help you achieve your goals.

Frequently Asked Questions (FAQ)

Automation improves efficiency, reduces human error, and enhances process reproducibility, ensuring better control over production quality.

Single-use bioreactors reduce contamination risks, eliminate cleaning requirements, and provide greater flexibility for scaling up production.

Digital twins allow real-time simulation of bioprocesses, helping to predict and improve outcomes before implementing changes in actual production.

Sustainability is crucial for reducing waste, optimizing resource use, and ensuring environmentally friendly biomanufacturing processes.

ATMPs (Advanced Therapy Medicinal Products) include gene and cell therapies that offer innovative treatments for previously untreatable diseases, requiring specialized bioprocessing technologies.