If you have ever wondered how certain medicines, foods or even biofuels are made, the answer lies in a piece of equipment called a bioreactor. In this article we explain in simple terms everything you need to know about bioreactors. So that when someone asks you "What is a bioreactor?", you can answer easily.

What is a bioreactor?

A bioreactor is a device or vessel in which cells or microorganisms are grown under controlled conditions to produce specific substances. These substances can range from drugs, such as antibiotics and vaccines, to foods such as yoghurt or beer, and even fuels such as ethanol.

This equipment is fundamental to modern biotech. They provide a controlled environment where cells or microorganisms can grow and produce desired products efficiently. The ability to control variables such as temperature, pH, nutrient concentration and the amount of oxygen allows the production and quality of biological products to be optimised.

History and evolution

The history of bioreactors dates back to ancient times with fermentation, used to make bread, beer and wine. The first equipment were simply earthenware vessels used by civilisations such as the Greeks and Romans to ferment food under anaerobic conditions.

In the 20th century, modern bioreactors began to develop with the industrial production of penicillin during World War II. This marked a significant breakthrough, allowing large-scale production of antibiotics and other biotechnological products.

Types

There are different types of bioreactors made for various applications and cell cultures.

- Stirred Tank: These are the most common and consist of a tank with an agitation system that mixes the contents to ensure an even distribution of nutrients and oxygen.

- Photobioreactors (PBR): Incorporate a light source, either natural or artificial, to grow phototrophic organisms such as cyanobacteria, algae or moss plants. These organisms use light through photosynthesis as a source of energy.

- Wastewater treatment: Use inert media with high surface area for biofilm growth or aeration systems to create activated sludge, reducing the biochemical oxygen demand (BOD) of contaminated water.

- Specialised tissue: Designed to grow cells and tissues that require structural support. They are used to recreate organ structures in the laboratory, including cardiac, muscle, ligament and cancer tissue models.

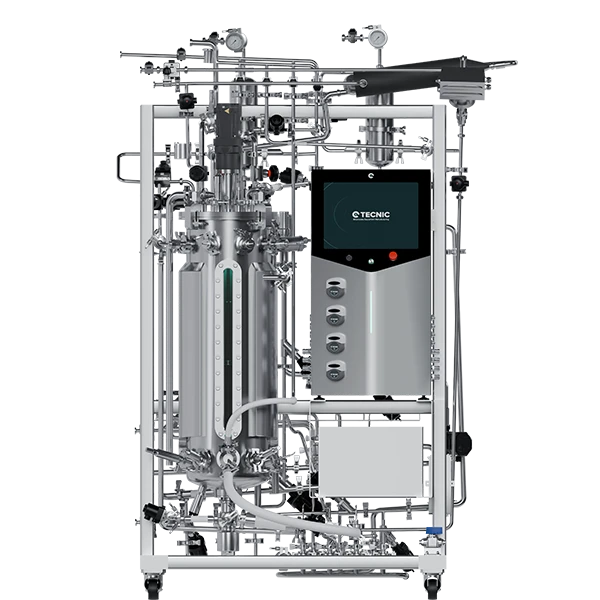

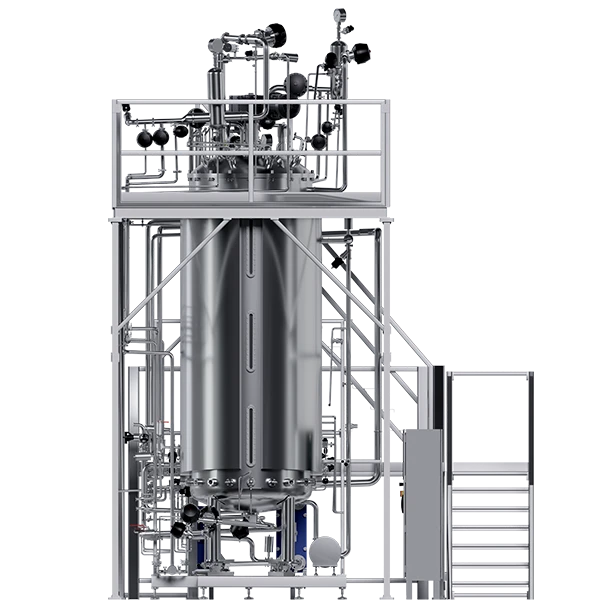

Main components of a bioreactor

To understand how a bioreactor works, it is important to know its main components:

- Vessel: The container in which the cells or microorganisms are grown. They can be made of stainless steel, borosilicate glass and single-use.

- Stirring system: A mechanism for mixing the contents of the bioreactor, ensuring an even distribution of nutrients and oxygen.

- Control systems: Equipment to monitor and adjust parameters such as temperature, pH, dissolved oxygen and nutrient concentration.

Feeding and removal systems: Devices to add nutrients and remove waste products, maintaining the optimal environment for cell growth.

How does a bioreactor work?

To understand how it works, imagine a large tank where microorganisms such as bacteria, yeast, plant and animal cells are placed. These microorganisms need certain conditions to grow and produce what we need. This is where the bioreactor comes in, as it provides:

- Nutrients: Essential food for the microorganisms, such as sugars, amino acids and vitamins.

- Oxygen: Necessary for some microorganisms to breathe. In aerobic bioreactors, oxygen is supplied by bubbling or stirring.

- Temperature: A warm, stable environment, controlled by heating or cooling systems.

- pH: The appropriate level of acidity or alkalinity, adjusted by the addition of acids or bases.

- Agitation: Movement to keep everything well mixed and ensure that microorganisms have access to nutrients and oxygen.

All of these factors are monitored and adjusted to ensure that the microorganisms are in optimal conditions for growth and production.

Applications of bioreactors

Bioreactors have many applications in different industries, among them:

- Pharmaceutical industry: production of antibiotics, vaccines and other biological drugs. For example, the production of insulin using recombinant cell cultures.

- Food and beverage: Fermentation of products such as beer, wine, yoghurt and cheese. Bioreactors allow the controlled and efficient production of these products.

- Industrial biotechnology: Creation of enzymes and proteins for different uses, such as detergents, textiles and foodstuffs.

- Energy: Production of biofuels such as ethanol and biodiesel from biomass. Bioreactors allow the conversion of organic materials into renewable fuels.

- Wastewater treatment: Use of microorganisms to break down and remove pollutants from wastewater.

Innovations and future of bioreactors

Research and development in the field of bioreactors continues to advance, with innovations such as single-use bioreactors ⇀ reducing the risk of contamination and cleaning costs. In addition, the development of automated bioreactors and real-time monitoring systems is improving the efficiency and control of biotechnological processes.

In the future, bioreactors are expected to play a crucial role in the sustainable production of food, energy and pharmaceuticals, contributing to solving global challenges such as climate change and food security.

Conclusion

In short, a bioreactor is like a miniature factory for microorganisms. Thanks to them, we can produce a wide range of products that benefit our health, food and energy. The ability to control and optimise culture conditions makes bioreactors an essential tool in modern biotechnology. If you are interested in the world of biotech, bioreactors are a key piece of equipment worth knowing about.

Frequently Asked Questions (FAQ)

A bioreactor is a device where cells or microorganisms are grown under controlled conditions to produce specific substances, such as drugs, food or biofuels.

Bioreactors are essential because they provide a controlled environment, which optimises growth and production of biological products by controlling variables such as temperature, pH, nutrient concentration and oxygen.

- - Vessel: Where cells or microorganisms are cultured, made of stainless steel, borosilicate glass or single-use materials.

- - Agitation system: Mechanism for mixing the contents of the bioreactor and distributing nutrients and oxygen.

- - Control systems: Equipment to monitor and adjust parameters such as temperature, pH, dissolved oxygen and nutrient concentration.

- - Feeding and disposal dystems: Devices for adding nutrients and removing waste products.

A bioreactor provides a controlled environment where nutrients, oxygen, appropriate temperature, controlled pH and agitation are provided to promote the growth and production of micro-organisms or cells.

- - Pharmaceutical industry: Production of antibiotics, vaccines and other biological medicines.

- - Food and Beverage: Fermentation of products such as beer, wine, yoghurt and cheese.

- - Industrial Biotechnology: Creation of enzymes and proteins for detergents and textiles.

- - Energy: Production of biofuels such as ethanol and biodiesel.

- - Wastewater treatment: Use of microorganisms to break down and remove pollutants from water.