In this article, we will explain in detail what TFF system (Tangential Flow Filtration) is and what it is used for, providing an overview of its applications, advantages, challenges and future.

Introduction to TFF systems

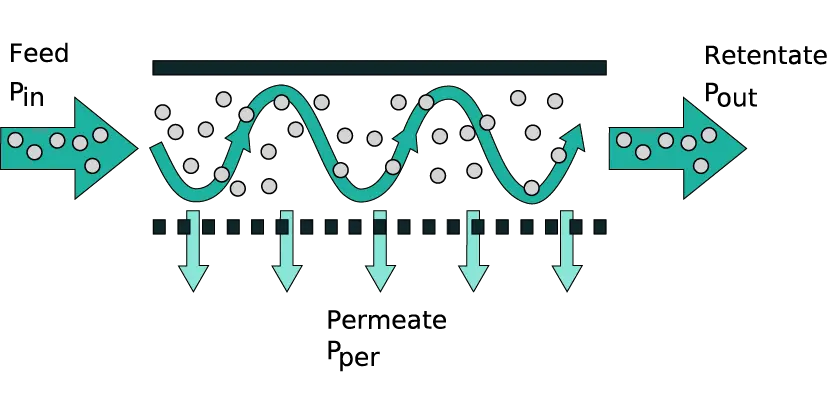

Tangential Flow Filtration is an advanced technique used to separate and purify biomolecules, such as proteins, cells and other biological components. Unlike direct filtration, where the flow passes perpendicularly through the filter, in TFF the flow passes tangentially to the membrane surface. This approach allows for a more efficient filtration process, minimising particle build-up on the membrane and prolonging its life.

The TFF system is especially useful in applications where it is crucial to maintain the integrity of biomolecules and where high separation efficiency is required. It is used in research laboratories and industrial production.

History and evolution of TFF

Tangential flow filtration was initially developed in the 1970s and 1980s, mainly for protein purification and cell separation in research laboratories. Since then, TFF has evolved significantly and has been integrated into large-scale production processes.

Originally, the membranes used in TFF were less efficient and more prone to fouling. However, with advances in materials science and membrane engineering, more durable and efficient membranes have been developed. These advances have enabled TFF systems to become a crucial tool for the purification and concentration of biological products, contributing to the mass production of biological drugs and other biotechnological products.

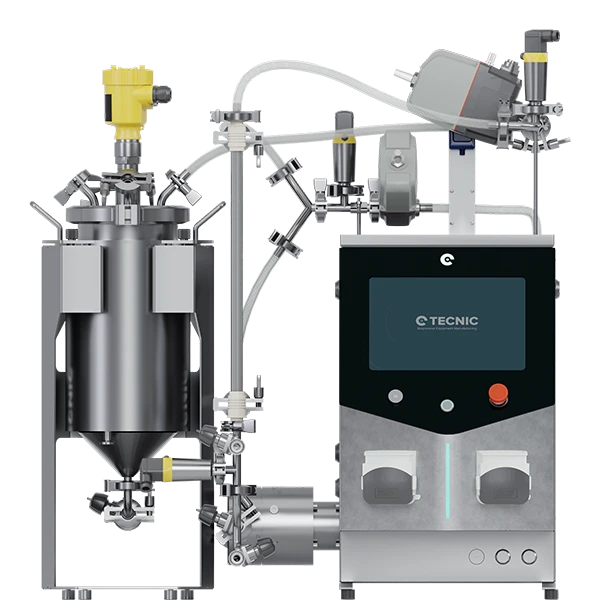

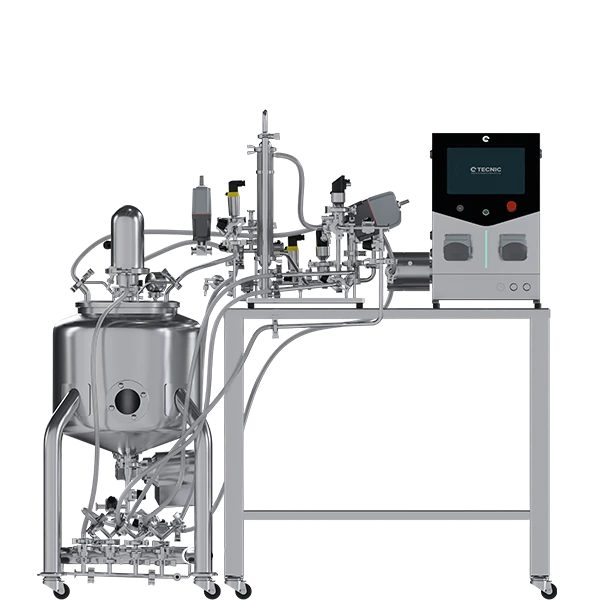

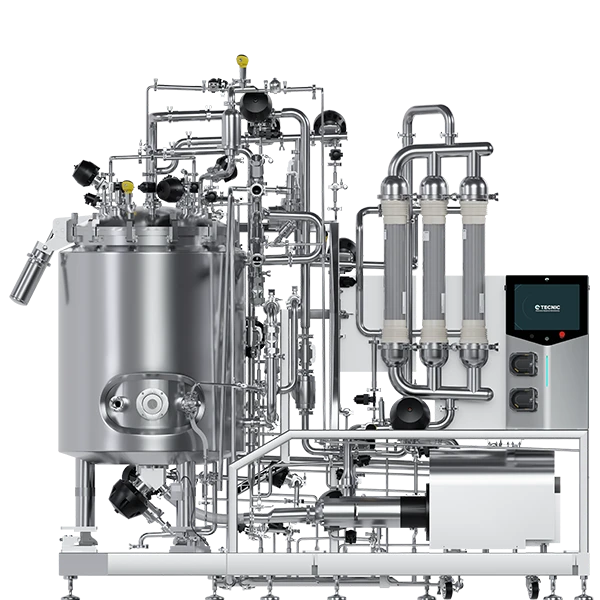

Types of TFF Systems

Several types of TFF systems are designed for different applications and needs

How does TFF system work?

In a TFF system, the solution is pumped tangentially along the surface of a filter membrane. This tangential flow keeps the particles in motion, reducing build-up on the membrane and improving filtration efficiency. The process can be summarised in the following steps:

- Solution preparation: The solution containing the biomolecules or particles to be separated is prepared and placed in the TFF system.

- Pumping and filtration: The solution is pumped through the membrane module, where the tangential flow keeps the particles in motion and prevents clogging of the membrane.

- Permeate and retainer collection: The filtrate (permeate) is collected in the permeate vessel, while the separated particles (retainer) are collected in the retainer vessel for further processing or disposal.

Applications of TFF systems

- Pharmaceutical industry: purification and concentration of proteins, antibodies and other biological products. TFF is essential in the production of biological drugs, such as vaccines and monoclonal therapies, ensuring proper purity and concentration of the final products.

- Biotechnology: Separation and purification of cells, viruses and other biological components. In biotechnological research, TFF is used to prepare pure and concentrated biological samples for various studies and applications.

- Food industry: Concentration of juices, dairy products and other liquid foods. Flow filtrations systems helps to improve the quality and stability of food products by removing impurities and concentrating the desired components.

- Water treatment: Clarification and purification of wastewater and drinking water. TFF is used to remove contaminants and unwanted particles from water, improving its quality and making it suitable for reuse or consumption.

Types of Filtration

Within the field of filtration technology, there are several types that are used depending on the size of the particles to be separated and the specific application:

Conclusion

In summary, tangential flow filtration (TFF) is an advanced technique that enables the efficient separation and purification of biomolecules and particles. Due to its design and operation, cross flow filtration has become an essential tool in modern biotechnology and various industries. The ability to maintain a continuous and controlled flow, together with the reduced risk of clogging, makes TFF systems the preferred choice for many industrial applications.

If you are interested in the world of biotechnology, Contact TECNIC team for advice and help in choosing from our wide range of TFF equipment, with filtration areas ranging from 0.1m² to 36.3m²

Frequently Asked Questions (FAQ)

A Tangential Flow Filtration (TFF) system is an advanced technique used to separate and purify biomolecules such as proteins, cells and other biological components. Instead of flowing perpendicularly through the filter, in TFF the flow passes tangentially to the membrane surface.

In a TFF system, solution is pumped tangentially along the surface of a filter membrane. This tangential flow keeps the particles in motion, reducing build-up on the membrane and improving filtration efficiency.

Depending on the size of the particles to be separated and the specific application, there are several types of filtration, including microfiltration, ultrafiltration and nanofiltration, each suitable for different separation and purification needs.

Crossflow filtration is another name for tangential flow filtration (TFF). This method allows for more efficient filtration by keeping particles in motion and reducing build-up on the membrane.

Some challenges include optimising process conditions for different types of biomolecules, maintaining membrane integrity, and managing the operational and maintenance costs of the system.